.Combination between alloy aluminum cylinder and plating layer

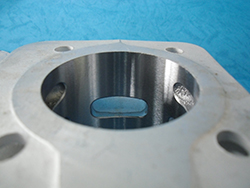

| ● | destructive inspection of nikasil cylinder |

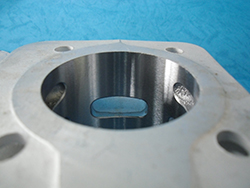

| ● | destructive inspection of chromium plated cylinder |

The plating layer may easily crack and blister to obstacle the normal operation of cylinder when the combination is weakened due to the stress difference between alloy aluminum cylinder and plating layer on account of cylinder temperature dramatically changed with the expansion factor of aluminum larger than plating layer under engine high speed operation

Thus, the alloy aluminum chromium plated cylinder or alloy aluminum nikasil coating cylinder of “SHINHER POWER” should completely comply:

- ■ The coating layer should not have any crack, peer, and

blister after 1 hour in steady temperature 300±10 T℃

and then placed in air to cool down to room temperature.

- ■ The coating layer should not have any crack, peer, and

blister after 5 minutes in steady temperature 220±10 T℃

and then placed in 5 T℃ cold water quickly.

■ No peer or apart of coating layer should be found at the

combination edge sawed by saw blade in the destructive

inspection.